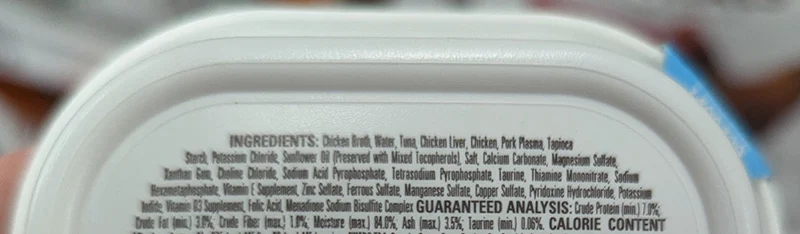

Unlike the detailed list of nutritional requirements for human food, pet food in North America must only report on four main values in their Guaranteed Analysis on the label: protein, fat, fiber, and moisture. Additional nutrients must be included if they are called out specifically on the label, but manufacturers can also voluntarily add more nutrients to provide consumers with more information or further demonstrate the nutritional value of their products. Surprisingly, one such voluntary „nutrient” that frequently appears on labels is „ash.” However, the presence of ash in the Guaranteed Analysis does not indicate the presence of literal ash in the food; instead, it explains the process through which the mineral content is determined.

As Michael Jakob discusses in a recent Feed & Additive article, mass loss on ignition/combustion with an air oven or a muffle furnace is one of the most common methods to determine ash content. Similar methods, at lower temperatures, can be used to determine moisture in food samples, which is another value important for labels and regulation. This sort of thermogravimetric analysis is widely accepted for food and feed analysis in laboratories around the world.

This process is usually quite lengthy and labor-intensive. Samples must be measured and recorded at multiple stages, with care taken not to introduce atmospheric contamination throughout the process. Since the analysis concludes when the weight remains consistently constant, they are usually run for multiple hours to ensure the sample is ready, which often wastes both time and energy. Many automated thermogravimetric analyzers are small, only able to handle one or two samples at a time, which can lead to what feels like an endless cycle of going round and round.

Throughout the analysis sequence, the sample carousel moves each crucible sequentially onto the integrated balance pedestal, continuously monitoring the weight and recording all measurements. The TGA801 automatically ramps up the temperature for ash determination once moisture weight constancy is achieved for all samples. The analysis will end precisely when weight constancy for the final step has been achieved, saving time, money, and uncertainty. During this process, the operator is able to walk away from their instrument and focus on other tasks, with Cornerstone® Mobile, our mobile software link to LECO instruments, able to alert at cycle completion or if any problems arise.

Fill out the form below to read an app note on moisture and ash determination in animal feed with the TGA801. You may also view a recent on-demand webinar featuring a live demonstration of the TGA801 in action to see what you’ve been missing.